A reminiscence of 2 decades ago in Ngwata area of Makueni county in Eastern Kenya,Africa, gives a totally different sense of current climatic conditions reality.The area is close to two notable global landmarks i.e. Tsavo national park, the largest national park in Kenya and one of the largest in the world and the Chyulu hills, one of the youngest volcanic ranges in the world.

About 15 years ago, rain seasons were certain but with climate change the area is slowly losing its glory. The current trends are marked with prolonged dry spell and water is increasingly becoming a very scarce resource.During rainy seasons, excessive downpour is experienced but within a very short period (that cannot support full crop growth cycle). Inhabitants of the aforementioned area would initially source water from a main supply pipeline running from Umani springs to Mtito Andei a distance of about 40km but that is now history as the springs are now drying up.

This crisis has overtime necessitated drilling of boreholes by individual farm owners, or with the help of philanthropic organisations.This was thought to be a long-term solution to the problem of water shortage only to find out that it isn’t as all the boreholes drilled within the area produce water with extreme hardness levels compromising highly its domestic utility. The cost of a 5 gallons Jerrican has increased from 1Ksh(0.01USD) to between 20Ksh and 50Ksh (0.20USD-0.50USD) within a period of 10yrs while the quality continues to deteriorate.

Delving deep into the root of problem to come up with a workable efficient water crisis solution, water pans for rainwater harvesting and investing in purification plants for the same then storing enough for use during the dry seasons becomes a reliable option.

A big open tank located close to the old Kenya railway,with a capacity of approximately 132000 gallons originally used as a water reservoir for steam engine trains in the ancient Kenya collects the runoff when rain seasons come.

Conceptualisation of taking advantage of the water that collects in it during the rain seasons, treating it and storing it in a reservoir is a perfect idea to help the immediate owners of the farm where the tank is situated who are farmers and have a myriad of fruit trees facing the danger of withering as well as help the people in the

neighborhood who have to walk long distances on daily basis in search of water which in many cases is of substandard quality.

Engineering considerations were carried out and a design for the water treatment plant

generated as well as the Bill of Quantities thereof for review by Partnerships For Change Leadership and funding consideration which was hurriedly done and the project carried out with installation adhering to the design per spec which was done with great room expansion incase more resources are available for the same in future.

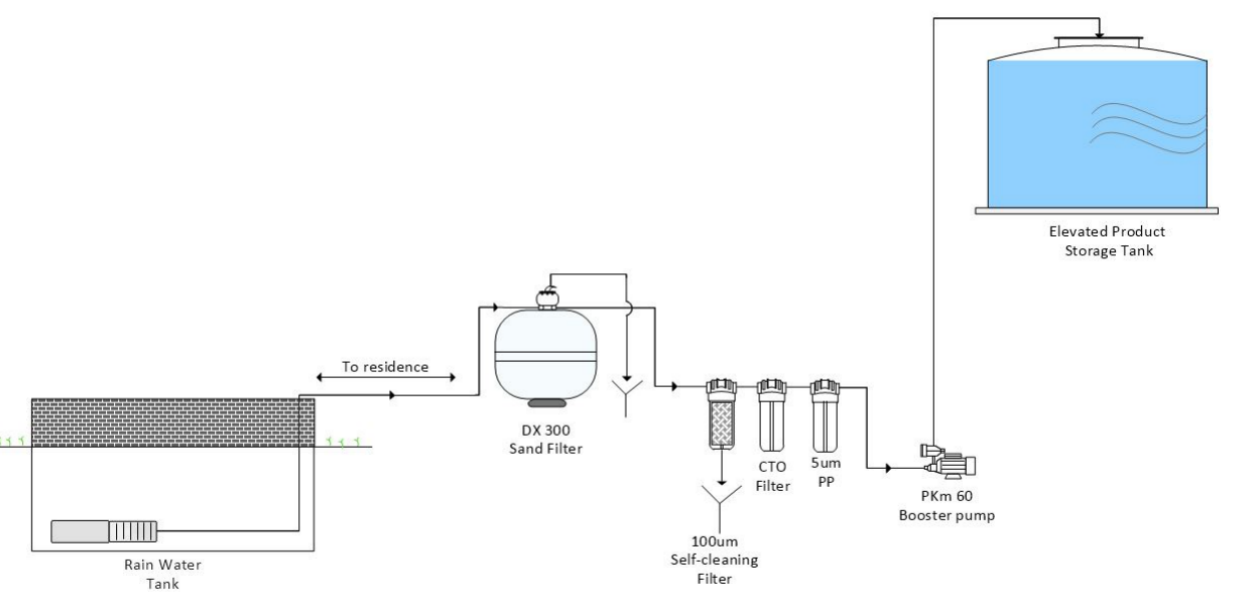

The process of the water filtration is as explained:

Process Flow

Rain water accumulates in an open underground tank that is located 150m from the homestead.A

submersible pump will be required to lift the poor quality water and transfer through a pipeline to

the homestead where the purification plant will be situated.

DX 300 Sand Filter

Combines the latest filtration technology

- Specially designed internal collector laterals providing maximum filtration and

backwashing efficiency and minimal media loss.

- High-grade silica sand media for exceptional filtration performance.

It must be remembered that the most important aspect of a pool's appearance is the quality of its

water. The key to this is efficient filtration and a pool's filter is the one piece of equipment where

compromise does not pay. DAYLIFF 'DX' filters are quality products which have been carefully

designed to combine the highest standards of performance with outstanding reliability and ease of

operation. With a DAYLIFF filter clean, sparkling water is assured at all times.

100 micron Self-Cleaning filter

Self-cleaning filters work on a flow direction of outside to inside. Unfiltered fluid enters the filter

housing through the top tangential inlet connection. Contaminants are deposited on the outer

surface of filter elements and clean filtrate passes through the inside diameter of the element, then

removed through the top tangential outlet. Once the differential pressure across the system reaches

the pre-defined level of pressure drop, inlet and outlet valves shut down and the drain and

backwash valves open for a defined interval of time. During this process, debris deposited on the

outer surface of the element shall be drained out and collected through the bottom drain. This cycle

continues as per pre-defined settings and process requirements.

CTO Filter

CTO is an acronym for Chlorine, Taste, and Odor. A filter recommended for CTO removal will

produce water that is much clearer in color with a more appealing taste and elimination of odors.5 micron PP Filter

Made of poly propylene material for further sediment filtration.It has very tiny pores of 5 micron

diameter

PKm 60 Booster pump

This is a robust, reliable pump that will be used to lift the treated water to an elevated 5000 Litres

Reservoir for storage.

Testing of the installed equipment was done and the operator training conducted.This water treatment system proved to work perfectly and now 4 months after the installation the community really appreciates this amazing initiative thanks to Partnerships For Change.

Written By:

Alphonce Muia.

Director,Environmental Science.

Partnerships For Change.